Samhwa ACE repays customers with the best technology

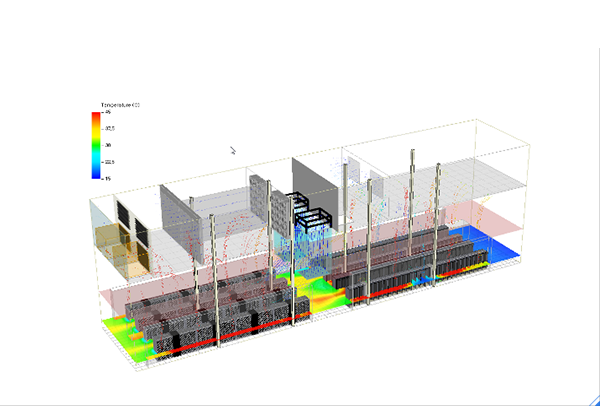

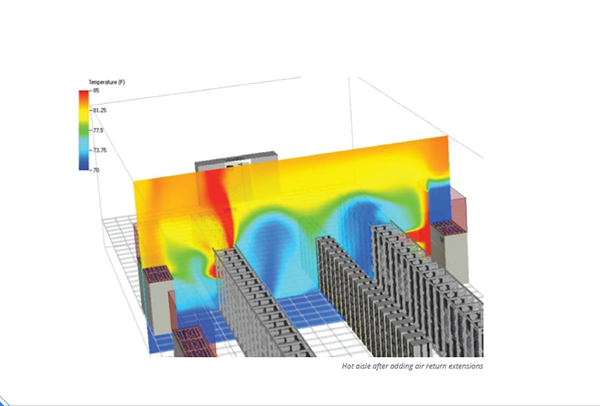

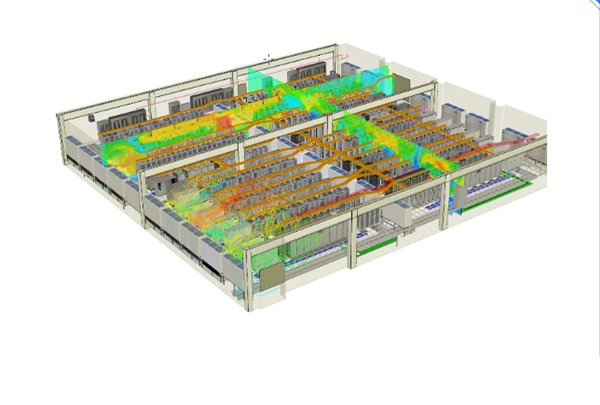

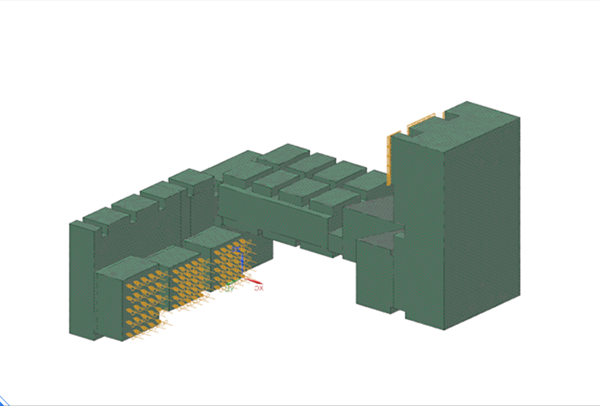

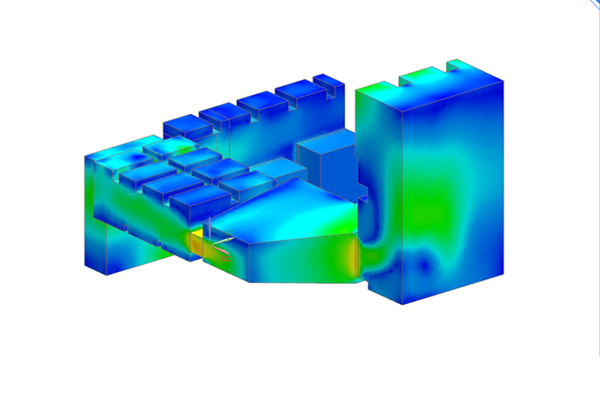

The actual situation of a data center is modeled, and air circulation and temperature change are expected. By simulating the data center, issues in various environments and conditions in architectural structures, AHU, power for each rack, and equipment types, etc. can be identified, and optimum measures can be drawn up and taken. World-renowned enterprises such as Google, Facebook, Dell, Cisco, etc., which operate data centers and run their business, also conduct analyses to verify, execute, and review basic concept designs, and they can estimate the accuracy and energy efficiency (PUE).

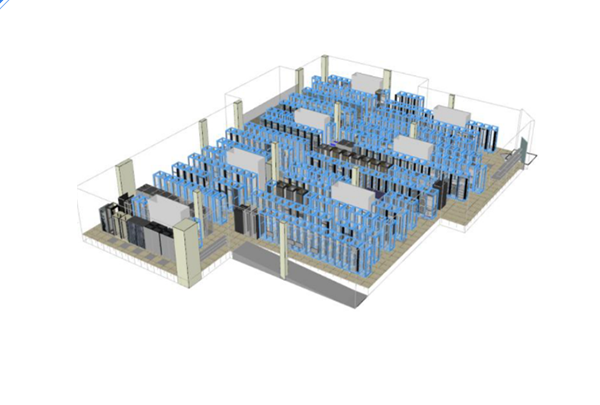

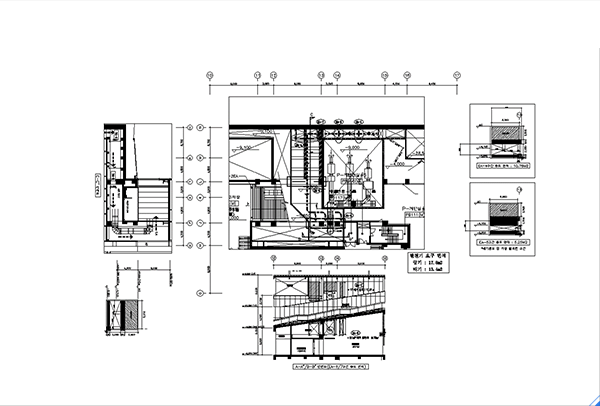

It is possible to confirm and review performance through 3D structure analysis modeling and simulation for 2D structure before the actual manufacture, installation, and construction and to correct and improve design models based on the result of confirmation/review. Especially, since it is possible to confirm whether shapes, materials, and various complex conditions are available without any problem in actual situations, the costs of manufacture, installation, and construction may be significantly reduced.

Supported with the smart all-in-one integrated control/monitoring technology to control AHU and each part at the center and to monitor the operation and status of such parts